Sanitary Gasket Plate Heat Exchanger

Sanitary plate heat exchangers are designed to meet stringent sanitary standards and regulations. they are used in dairy, food, beverage and other hygienic applica- tions requiring gentle product treatment, long operating times or superior cleanability. They are often constructed with smooth surfaces, rounded corners, and no dead zones to minimize the risk of bacterial growth and facilitate thorough cleaning and sterilization.

The gaskets used between the plates are also made from food-grade materials that can withstand high temperatures and maintain a hygienic seal.

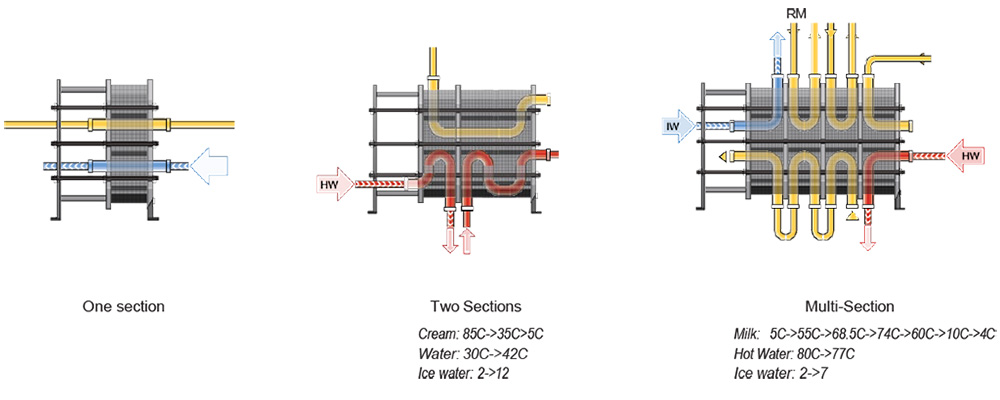

Sanitary range plate heat exchangers uses glue-free gaskets made from FDA-com- pliant materials that are easy to maintain and have a long service life. The frame can be used for multi-section applications (eg for pasteurization) and is easy to disassemble for inspection, cleaning, and service. Connection plate corners are interchangeable and heat transfer plates can easily be added or removed, so it is quick and easy to modify if process conditions change.

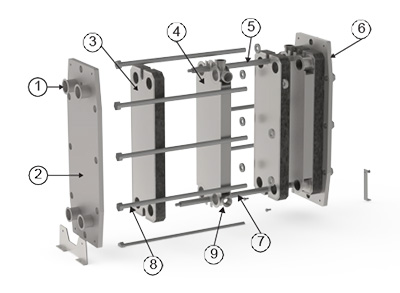

1. Sanitary Connection

2. Front frame plate

3. Plate pack

4. Connection plate

5. Up carrying bar

6. Pressure plate

7. Guide bar

8. Tightening bolts

9. Corner connections

Applications

• Biotech and Pharmaceutical

• Food and Beverages

• Home and Personal care

Benefits

• Superior hygienic safety – plates designed for food applications

• Gentle treatment of sensitive products

• Uncompromising cleanliness

• Flexible configuration – possible to rebuild the heat exchange

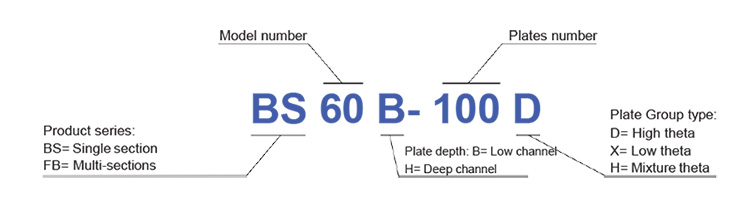

Model Code Explaination:

Specification data:

|

Model |

Width |

Height |

Ver�cal Port distance |

Horizon Port distance |

Pressure |

|

BS30 |

180 |

480 |

357 |

60 |

10 |

|

BS60 |

320 |

960 |

640 |

140 |

10/16 |

|

BS100 |

454 |

1085 |

719 |

225 |

10/16 |

|

BS150 |

610 |

1815 |

1294 |

298 |

10/16 |

|

FB60 |

310 |

905 |

640 |

140 |

10 |

|

FB100 |

442 |

1053 |

719 |

225 |

10 |

|

FB150 |

610 |

2122 |

1294 |

298 |

10 |