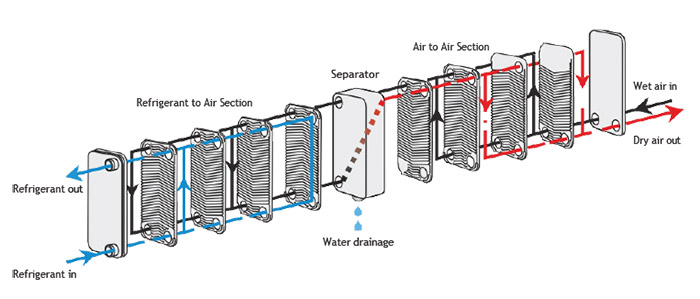

How it works

Refrigerated air dryers separate humidity from compressed air by cooling the air in an evaporator. This cooling effect comes from the evaporation of the refrigerant. As the air cools, it looses its ability to hold moisture. The condensate is then collected and removed in a separator.

A heat recovery air to air heat exchanger that reheats the air to ambient temperature is in the Airdryer for optimal efficiency.

This humid air then moves into a separator and then dry air is preheated in the heat recovery side. The total air side pressure drop is typically 20-30 kPa (3-4 psi)

Introduction

AL series Air dryer are brazed plate heat exchangers designed for separation of humidity in compressed air.

Applications

Compressed air drying

Benefits

• Compact

• Easy to install

• Self-cleaning

• Low level of service &maintenance is required

• All units are pressure and leak tested

• Gasket free

Design specification

Air side:P = 7 bar(g), T dew = 3°C, ∆P = 20 kPa, T in = 35°C, T out = 27°C

Refrigerant R134a, T evap = 0°C, SH = 5K

Max working Pressure

Air side: 16 bar(g) @ 20°C

Refrigerant side: 35 bar(g) @ 20°C

According to PED

Material Specification

Mainparts: Stainless steel

Brazing material: Copper

Separator Efficiency rate

Droplets size: 95%

Mounting

Stud-bolts available

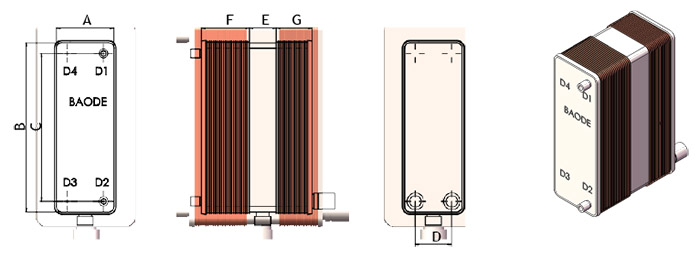

|

Model |

A |

B |

C |

D |

E |

|

AL14 |

76 |

206 |

42 |

172 |

44 |

|

AL26 |

111 |

310 |

50 |

250 |

50-100 |

|

AL95 |

191 |

616 |

92 |

519 |

85-276 |

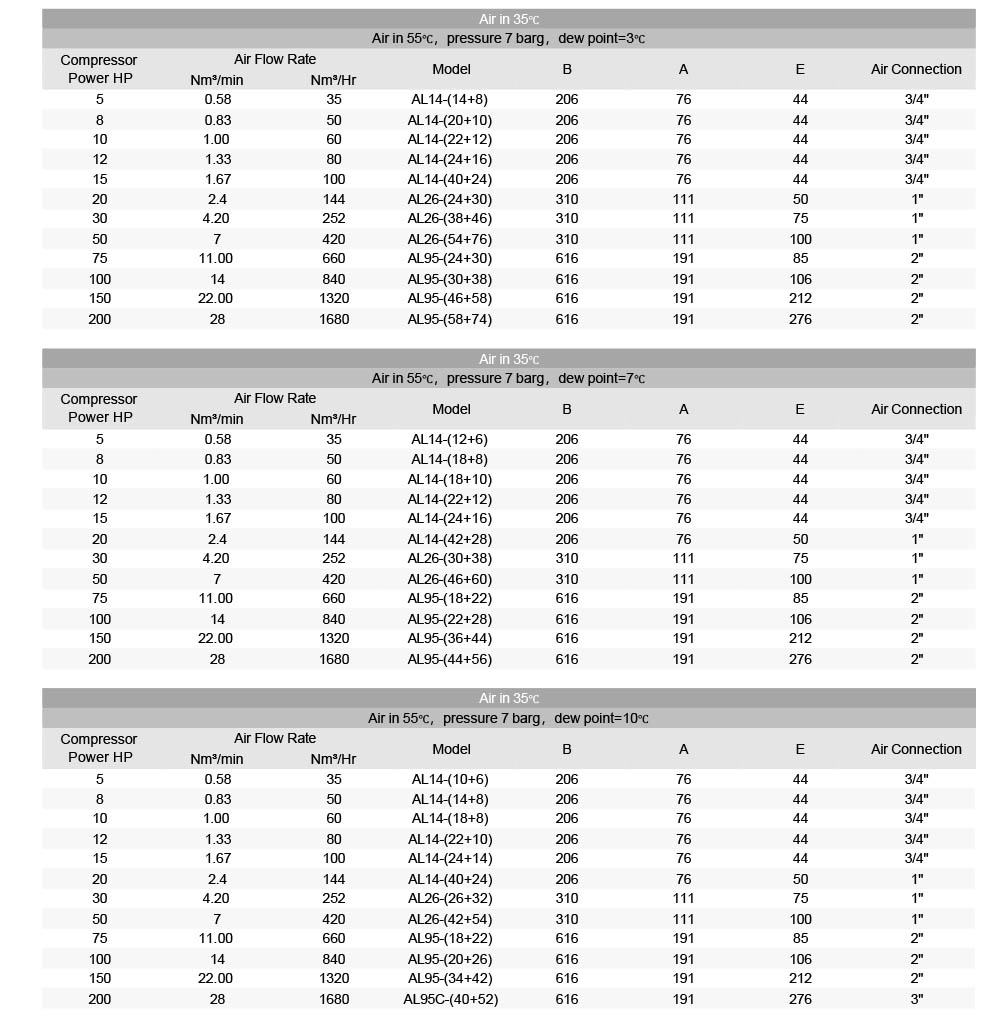

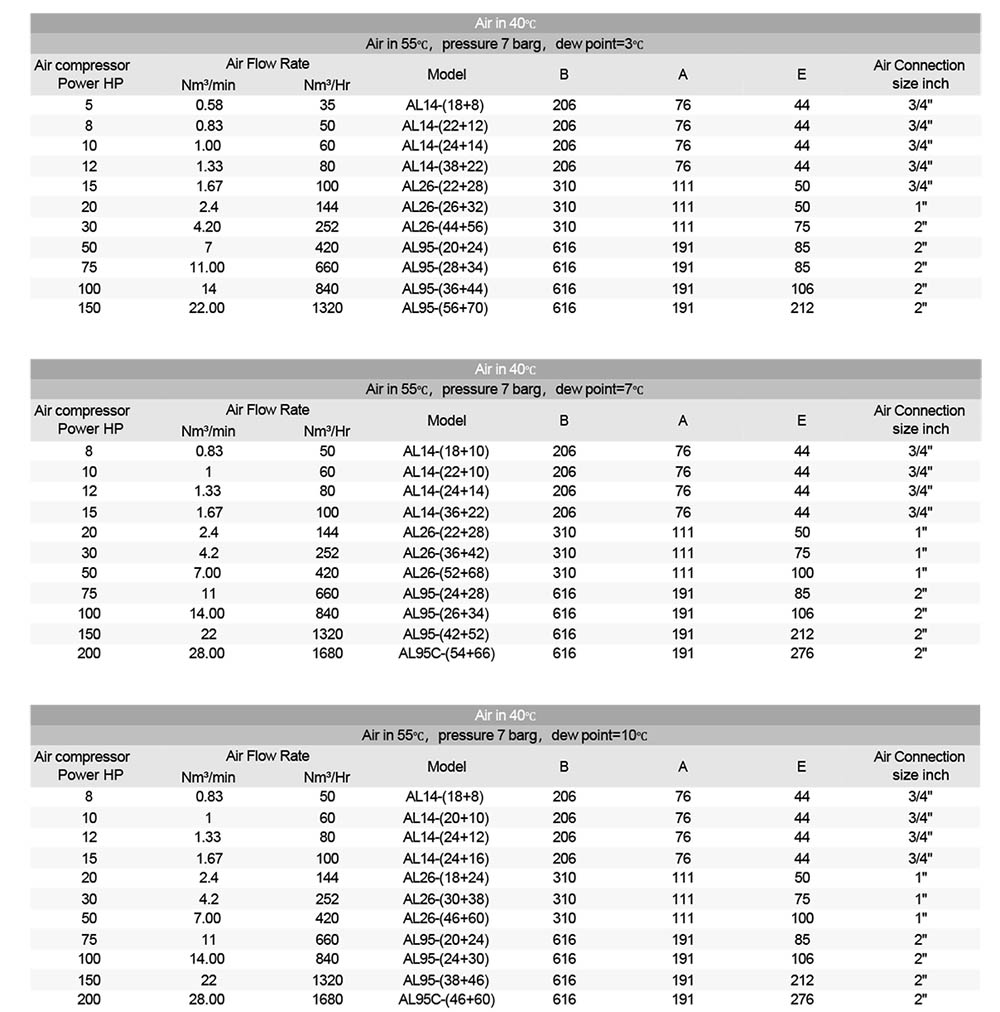

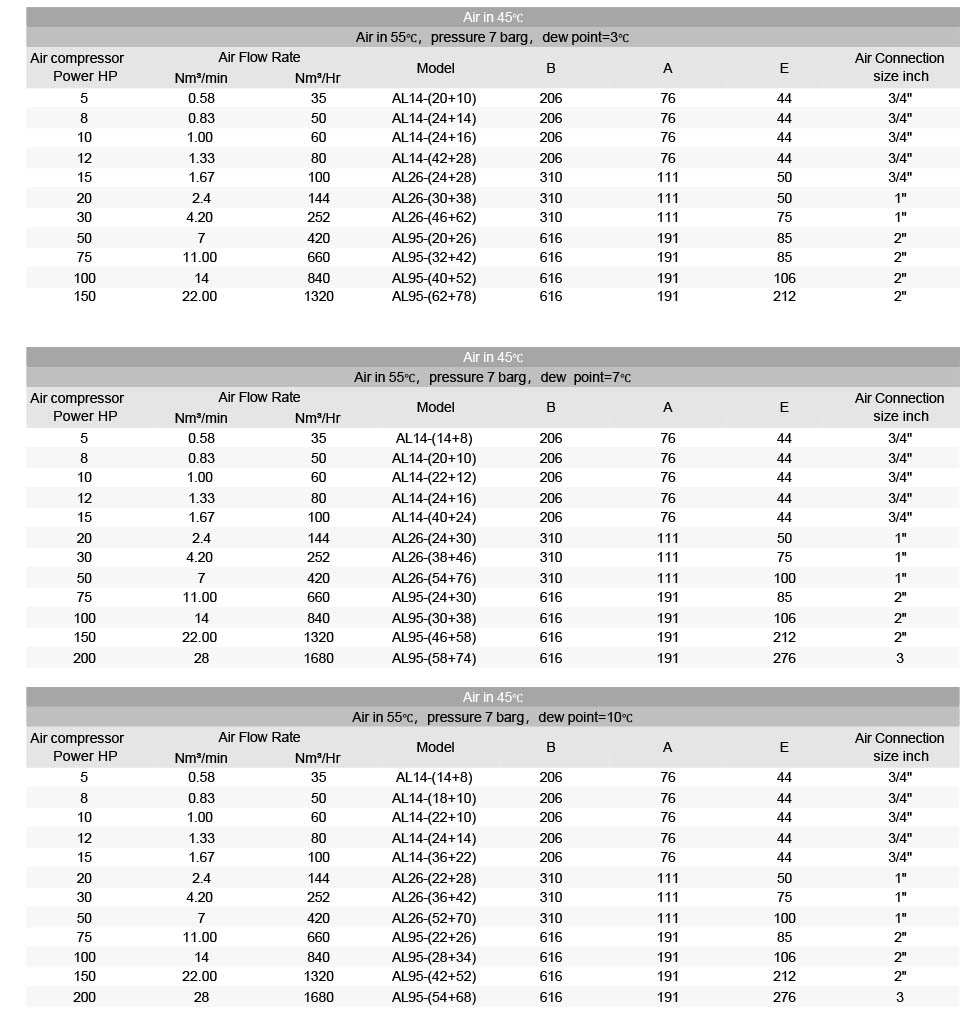

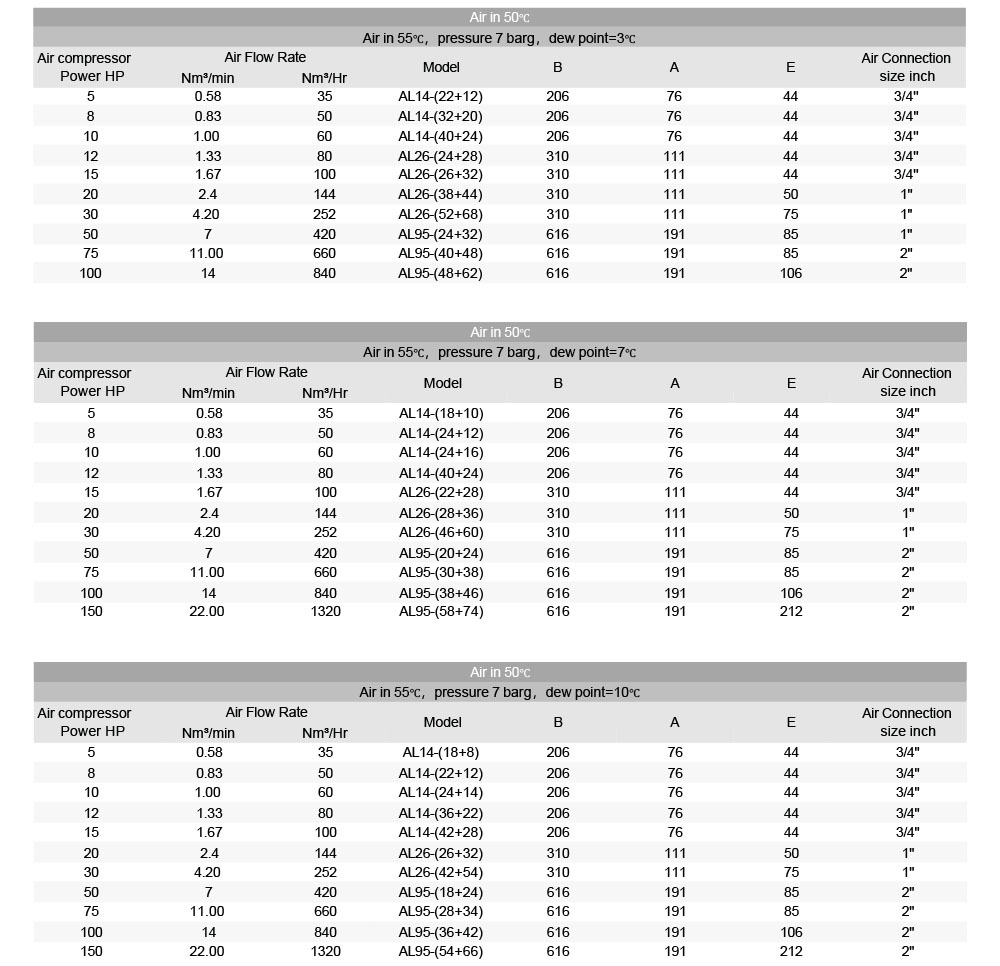

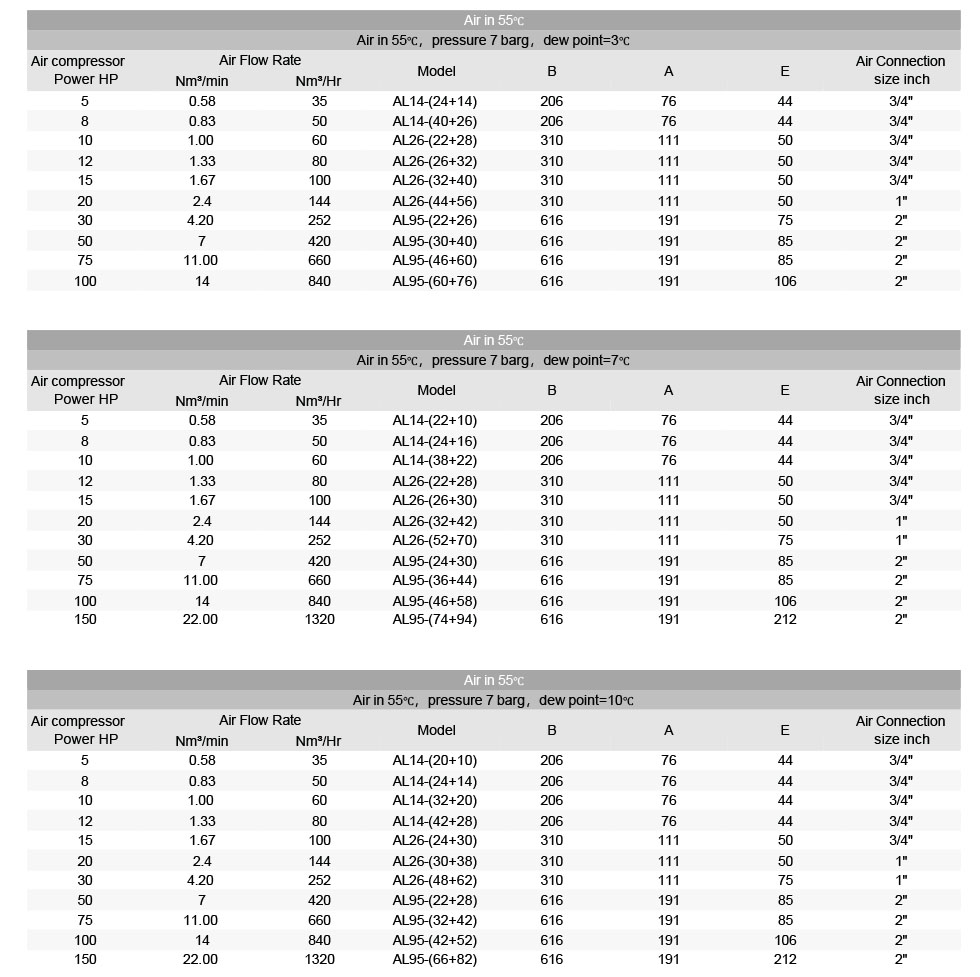

AirDryer Selection

"Dew point" is the temperature at which the water vapor in the air starts to condense in the water separator.

This is normally maintained slightly above the freezing point of water, 2-5 °C (35-40 °F).